Has it really been since April that I shared my last build-along progress? Yeah, that's not much of a surprise. Here's the deal, my construction methods aren't linear. I don't start working on X and continue until X is complete before starting on Y. I do a little work on X, reach something of a stopping point, then launch projects Y, Z and A1, shifting back and forth as need dictates. Sometimes the delays are financial. Sometimes it's weather related. Other times I run into a problem and need to figure out a work around before continuing. Sometimes it's a simple as it's raining or too cold or too hot. Progress is constant, but it makes little sense to share piecemeal progress on a build-along.

I'm at a point where I'm ready to share my bamboo screen. The images here, they begin a year ago and conclude last month. A year of work, off and on. That's a long span. My last update, I showed the work I'd done on restoring the booth I rescued from that closed Fuddrucker's in Houston. This ties in nicely to that, because this creates a space for the booth to reside. Follow: Bamboo is a major component of tiki bars, but you'll bankrupt yourself if you just try to go out and buy it. Far better (if you live in a climate where bamboo can grow) to set up a Craig's List alert to notify you any time someone posts bamboo for sale. This accomplishes two things--it gives you a heads-up when people post rattan furniture for sale, as most people don't have a clue what rattan is and just default to bamboo, and it lets you know when someone has cleared a lot overgrown with bamboo and they want someone to haul it off for free. I like both of those, but the latter is what I'm talking about now. Last fall there were several postings for free cut bamboo close together, and I picked up a good bit of 2" thick bamboo in both Austin and New Braunfels. Some of the culms were 20' or longer. I cut them into 9' lengths (the longest I could fit into my car) and later torched them. This gave me a lot of building material, as I knew I'd need a lot for my bamboo screen at the end of the covered patio, which will serve ad a symbolic as well as physical transition, marking the farthest extent of the Lagoon of Mystery. I think about things like this.

Now, I invite you to think back to May of 2018, where I ripped up and rebuilt the deck adjacent to the pool, renaming it the Hula Stage in the process. Most of the scrap wood left over from that rebuild was rotten, but several support beams were sound and salvageable.

From these, I was able to select two long 2x6 boards of approximately equal length. They had varying amounts of damage, but were generally devoid of rot or mold or fungus. In short, they were sound.

Before I could do anything with them, I had to remove two decades worth of screws, nails and random bits of metal that would do terrible, horrible things to any saw I used to cut the wood into usable sections. The took the better part of an afternoon, and I can assure you it was just as fun as it was when I was a pre-teen and my dad would take me out to some farm or other and make me spend the day pulling nails out of boards salvaged from some old barn or other. Which is to say, it's not fun at all.

Upon successfully denailing the boards, I cut them to equal lengths, then split one lengthwise using my table saw.

I then drilled pilot holes and used exterior wood screws to attached the split pieces to either side of the larger board, forming a U.

What'd I tell you? That's U if I ever saw one!

Next up was to bevel the edges, to make it look classy or something like that. Since I discovered how easy it is to bevel with my router, I bevel the shit outta everything.

After staining the wood with my go-to Minwax Special Walnut and applying several coats of Flood CFW UV weather protectant (it's western red cedar, which is rot resistant, but we all remember how neglected red cedar rotted like nobody's business during my deck rebuild) I added plastic-tipped furniture feet along the length of the bottom. This elevates the wood so it does not come into contact with the concrete patio. Concrete is a conduit for moisture, and moisture plus wood is a recipe for rot.

Remember all that bamboo I posted photos of at the top of this post? This is where we get the payoff. Some time over the winter I torched a bunch and then lined the culms up, using the U as a slotted base.

This is how the bamboo fits into the slotted base.

Here's another view. The base only keeps them stable front-to-back, but soon you'll see how the side-to-side is managed.

The culms vary in length, but they're mostly in the 8'-8'6" range. The ceiling here is 9' high, and the base adds 2"-3" total. After drilling pilot holes, and screwing large bicycle-hooks on either end of the ceiling, I added a bamboo culm as a cross beam. This serves the same purpose as the U base below to hold the bamboo stable.

Next, I drilled a hole through both the cross-beam and the vertical culm behind it.

Next, I tied the two culms together using fencing wire.

I then wired the tops of all the remaining vertical culms to the cross-beam. At this point I judged that drilling through all of them was an unnecessary step in over-engineering, so I just cross-tied each. That seemed to work just fine.

Next, it was time to cut bamboo to size for the next phase. Not all of the vertical culms are equally spaced. On either end, there's an open gap of roughly 16", and that space needs to be divided with horizontal bars. To cut bamboo to length, I use a fine-toothed saw, which makes narrow cuts and reduces splintering. Bamboo loves to splinter.

To ensure the ends of the bamboo cross pieces sit flush against the vertical culms, I pressed each end against the rounded front drum of my belt sander, which quickly cut a smooth, concave indentation.

I lined up the horizontal with the vertical, and marked where to drill.

I ran the fencing tie wire through the horizontal culm...

...then tied it securely to the vertical culm. The wire is rated for 20 pounds, so doubling it up gives me 40 pounds of leeway. I wouldn't recommend using this as a ladder, but for something I want to stand around and look pretty, it should do dandy.

I'd also added a lower cross-beam, about 3' off the ground. I filled in the 16" gap from the second cross-beam down with 3' lengths of bamboo. Since this was only for stability and the ties wouldn't be taking any stress, I went for fast and simple, using cheap jute twine to tie them. At some point I need to go back and weatherproof the twine, because jute's not terribly durable. On the other hand, it's easily replaced when necessary.

I tried tying a few of the 8' vertical culms to the second cross-beam with Manila rope, but it turned out to be so much simpler to just use more jute twine.

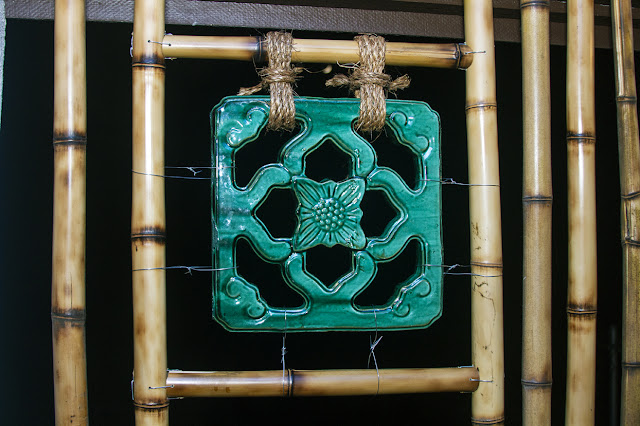

Now, we get to the reason for the 16" gap. Ceramic jade Chinese breezeway tiles have long been popular in the architecture of Chinese restaurants, but by the 1950s had found their way it tiki bars. The Mai Kai has them, as did the various Trader Vic's locations around the world. Today, it's a cool thing to have in a home tiki bar. It connects modern home bars to the historical lineage, so to speak. Alas, these are not common, and can be quite expensive. The best deal I could find was $40 each from some folks in Florida. Since the tiles are heavy ceramic, shipping was pretty steep. Not having the free cash to order everything I needed at once, I settled on getting two at a time. The first pair, I ordered November 2018. The final pair came to me this past September. Again, it'd be super-easy to just load up all our credit cards to get the building and decorative materials we need to finish the build, but there's a lot to be said for pay-as-you-go.

Trying to hang the tiles initially proved a challenge. Because they're heavy, I couldn't just hold one in place while I wired it in. It was awkward, and I needed two hands to tire wire securing the tile. I finally remembered I had a pack of zip ties, and these proved easy to use as a temporary hanger.

With the jade tile held in place by the zip ties, I was able to secure it with the fencing wire. I tried a number of different variations on how to tie it into place, but ultimately a simple loop worked best. Don't over-think it. I always over-think it.

Once I had the jade tile wired on all sides (three wires through each hole on the top, because that's the load-bearing side) I added Manila rope to cover the wires.

Here's the thing: If you've looked online or been to the Mai Kai, rope-tied jade tiles are easy to see. Unfortunately, all you see is the front, which is designed to be the most aesthetically pleasing. For the life of me, I could find no reference anywhere to how these ropes are tied, what knots are used, etc. What followed was several days of me trying to figure out how to make this work and not look terrible. I tried several variations--some quite clever, if I do say so myself--but nothing that rose above "Good in theory, terrible in practice."

This picture contains so much cursing and frustration. You have no idea.

Ultimately, I made peace with the fact my knots would not be elegant. I settled for functional, with the idea of making them as non-ugly as possible. For the main rope holding the tile to the bamboo, I used quarter-inch Manila rope, and tied the ends together in a square not inside the loops. Generally, I made four loops for each tie site. By placing the knot inside, it was mostly hidden from external view.

Then came the aesthetic secondary layer of rope, which wrapped around the rope already holding the tile to the bamboo. I had the notion that I'd be able to tuck this knot inside as well, but try as I might, I simply could not get that to work. There wasn't enough room, and the rope wasn't flexible enough for the space. I ended up using sisal rope for this, mainly because I'd run short on Manila rope. But the sisal rope was slightly easier to tie, and the lighter color made a nice contrast against the Manila rope. Ultimately, I tied the sisal in a square knot on the back side, which is facing out toward the yard where it would be less viewed.

To ensure all of these square knots stayed together and the whole thing didn't abruptly unravel on me, I slathered each knot with Shoe Goo, a strong, flexible glue that reminds me of rubber cement. It penetrated the fiber weave of the rope for a good grip, yet maintained flexibility. I don't know how it will hold up to the weather, but for now it's working well. There probably exists a knot that would've been a better choice for this particular task, but knots were always one of my worst areas in Boy Scouts. I think it's good to recognize one's shortcomings.

Once the glue set, I went to every knot and using tin snips (really massive scissors, if you don't already know) cut off the excess rope beyond the knot. To my surprise, this actually worked out fairly well. The resulting knots aren't nearly as glaring as I'd feared they would be, and the knots themselves are still holding fast.

I'm happy with the end result.

The ties between tiles with interceding bamboo cross-pieces worked out particularly nice.

And this is how it looks with the booth moved into position. I have to say how crazy close this looks to my original vision I had for this end of the Lagoon of Mystery almost three years ago now. The bamboo doesn't cut off airflow and isn't a full privacy screen, but in the evening it feels like the outside world at that end is held at bay. That's the effect I was hoping for. Sometimes halting, flailing efforts generate good results. This end isn't entirely finished yet, though. By next spring I hope to add a floating deck beneath the booth (more transitions!) and I need something to go there in the middle of that bamboo screen. It calls for a large mask or some other accent piece, no? On the opposite side, I need to build a thatched awning, because those jade tiles need protection and one very brief rain shower we had a couple of weeks back showed that area will get thoroughly soaked without it (the roof on that end of the house ends abruptly, without the protective overhang afforded the rest of the covered patio). There's still much work to be done, but this feels like a real milestone in the ongoing build-out of the Lagoon.

Now Playing: Tikiyaki Orchestra Aloha Baby

Chicken Ranch Central

Looks great!!! I like the images and commentary reels in the reader. I too am not exactly linear in my construction processes (A to B to C, etc). Looks like we might be fellow Texan Tiki enthusiasts. Fantastic!!

ReplyDeleteYour build is great! Your attention to detail is outstanding.

ReplyDeleteVery Nice!!!

ReplyDeleteAloha from Berlin, you think its hard to get Jade tiles in the U.S.

ReplyDeleteI am resorting to 3d printing a master and casting for slip mould of foam injection Mahalo Nui Loa

Ah, yes, I imagine so! I have experimented with 3D printing a jade tile and while the end result was a little smaller than traditional the results were impressive! Sounds like you have developed a viable work-around.

Delete