The holiday break resulted in my tackling a couple tiki-related projects I'd been putting off for a while. First up was a task of necessity. We've got a dog run/kennel on the side of the house, adjacent to the pool. It was kind of hastily improvised when we moved in, and not updated since. One of our beagles, Polkadots, has become something of a Houdini, escaping from the back yard on a regular basis, and the kennel has been the only thing keeping him in check. Until recently, when he discovered how to climb over the kennel gate (which, admittedly, was pretty low). Stopgap measures proved futile, so I bit the bullet and built a 5-foot bamboo gate to (hopefully) keep him contained. I harvested and torched all the bamboo myself, which was exceptionally time-consuming. On the other hand, commercially-available bamboo fence runs upwards of $90 for an 8' roll of 6' high fence, so yeah, I guess the sweat equity was worth it.

Traditional Japanese bamboo fencing is tied onto the support structure, but that didn't look viable for this job. Instead, I laid out the bamboo and drilled pilot holes through each culm, then used tan deck screws to attach them to the gate frame, which is just a basic kit available at Lowe's, Home Depot or other lumber yard. I used scrap 2x4s coated with Flood weather sealant to complete the frame, keeping costs down.

I need to point out that while I flame-treated the bamboo, I did not have the time to age it as long as I should have. Despite storing it in my heated garage with a dehumidifier running, the bamboo isn't anywhere nearly as dried out as it should be. It's pretty heavy still, and I anticipate a good deal of shrinkage in the months to come as it sheds that water weight.

To preserve its longevity, I needed to seal up the top so it didn't absorb additional water and rot. Most sections I was able to cut close to the node, which I capped with outdoor-rated wood putty, and then sealed with spar urethane once the putty was dried and sanded. Some sections weren't cut close to the node, however, so I used a can of "Good Stuff" foam sealant to fill in the space (that stuff expands a lot!) then, after trimming away the cured excess, capped with wood putty and a coat of urethane. The result is a bamboo gate that's waterproof from the top, at least. I filled the bamboo hollows on the bottom with the foam and then added a coat of urethane, but didn't go the wood putty route. There won't be any setting water at that end, so that should be sufficient to keep out splash and insects.

Once everything was dried, I installed the gate, setting two steel posts in fast-setting concrete. Doing this necessitated removing the rusting steel garden arbor the previous owners had left behind. Did you know rusting steel garden arbors harbor massive amounts of foul-smelling black water? I didn't either, but now I do. Digging post holes of sufficient depth through my predominantly clay soil was a good deal of work. Then I moved some stone slabs around to prevent the dogs from tunneling under. The gate latch, for now, is a chain-and-hook setup, but that will change once I replace the rest of the fence. There've been two escapes since the gate went in, but both those times were the result of my poorly-attaching the existing fence to the gate posts, which I have (hopefully) since rectified. We shall see how permanent the containment is from here on out.

Next up, a project I actually began way back in the spring. In fact, you can see the basic box-frame on top of the back bar in this post. When I realized I was going to add a back bar to my tiki paradise, I knew I wanted a rum shelf as a part of it. So I built a frame using scrap plywood and a chopped up 2x4 to craft a shelf roughly 42" long and 6" deep. The outside I would clad in bamboo sections roughly 6" tall--1" taller than the shelf itself.

I'm not sure how others would attach the bamboo, but I decided to wire it. To get everything to line up, I traced a guide line along the shelf roughly 4" up, then marked each of the bamboo sections at the same height. From there, I drilled two holes in both the shelf and the bamboo sections that, if my measurements were correct, lined up more or less accurately.

Then I fished 22 gauge jewelry wire through the bamboo. This Took some trial-and-error to perfect, but eventually I settled on a system where I fed in enough wire to reach through the end of the bamboo, at which point I bent it into a hook that slipped through the second hole. Then I pulled it through with a pair of needle-nose pliers.

Simply tying it off after slipping the wires through the holes drilled in the plywood did not offer anywhere near the stability I wanted. So I cut a wooden dowel to size and tied the wires over this. That helped considerably. Thicker wire would've helped as well. I started out with 24 gauge wire, but that snapped too often as I tied it. 22 gauge worked better, but I still had some breaks. 20 gauge might've offered better strength, but was more expensive for shorter lengths. Pick your poison.

Cutting all those sections of bamboo on the band saw took a lot of time. As did the drilling and the tying. Why are all my projects so time-consuming?

Once I got all those little boogers into place, I ran Titebond II glue down along the intersection of the bamboo and plywood, to add stability. It's not going to ever be rock solid, but as long as it isn't loose, I'm good. It's not like the bamboo should be subjected to a lot of stress. Then there was the open ends of the bamboo to deal with--I didn't want dirt and insects in there, this being an outside bar, after all. If it ain't broke, don't fix it is good advice, so I fell back on the process that served me well for the gate above--Good Stuff foam to fill the gaps, then a layer of outdoor wood putty finished with a sealing coat of spar urethane. Note that I didn't coat the entire piece of bamboo--the heat treatment gave them a resinous coating that is pretty much waterproof already, and paint, stain, sealants don't adhere well, either. In a few years, it may wear off sufficiently that a urethane coating will be necessary. Until then, it's only the ends I'm worried about sealing.

Then I attached the rum shelf to the back bar using a couple of galvanized mending plates. Simple and straightforward, plus it doesn't mar the back bar surface if, for some reason, the rum shelf ever needs to be removed. Note the grooves I have routered into the shelf supports. The reason is that, as originally conceived, the actual shelf would be comprised of translucent plexiglass, with a color-changing LED light strip strung along those grooves, illuminating the bottles of liquor from below. Alas, plexiglass isn't cheap--which I learned when building my tiki mug cabinets--and the thickness I needed for the rum shelf was even less cheap than normal. Rather than delay the implementation of the rum shelf whilst I waited for sufficient expendable funds to accrue, I simply cut a section of the laminate flooring from my office--the same stuff making up the bar top--to serve as the shelf. Quick and easy on the wallet. On top of that, it matches the bar and looks darn good, even if it doesn't light up from below.

And here is the rum shelf in action, playing host to a selection of tasty rums along with assorted liqueurs and the odd interloping vodka, bourbon and cognac. Now, the final project remaining to complete my back bar is installing the sink and running water. Which will be an undertaking best left for 2018. Regardless, I'm happy with the way it's shaping up as of now.

Here's wishing you a safe and happy 2018. Happy new year!

Now Playing: London Philharmonic Orchestra Symphonic Pink Floyd

Chicken Ranch Central

Sunday, December 31, 2017

Saturday, December 30, 2017

Tiki build-along, pt. 15

This is not so much a home bar build installment per se, but more of a tangential detour of the Christmas type. The Wife's favorite movie ever is "Joe vs. the Volcano," an early Tom Hanks/Meg Ryan comedy that is ambitious, weird, funny and downright surreal at times. I don't think it quite achieves what it's going for, but I appreciate the effort, and it's The Wife's favorite movie, so who am I to argue?

If you've seen the film, you'll remember early on that Joe, working in a fluorescent green hell hole of a job, has a brightly-colored hula lamp on his desk. This is the only color in an otherwise drab, soul-numbing environment. The lamp shade rotates and plays a song, "Joe's Lullaby." The lamp doesn't exist in reality--the prop department made it up specifically for the film. That hasn't stopped fans from investing tremendous effort to craft their own. There are lengthy threads devoted to it on various online forums. Having stumbled across one last year on Tiki Central, I realized I'd have to craft one as a Christmas gift to The Wife.

Easier said than done. I learned that the hula figure was a statuette originally produced by Treasure Craft back in the 1950s. The only way to get one was to scour Ebay. Which I did. Finding them wasn't a problem. Unfortunately, finding them at a reasonable price was. I finally lucked upon a set that was mis-labled on the auction site, which cut down on the competing bidders. I won. But when the package arrived in the mail, I learned just how fleeting my victory was. Here is the male statuette:

The hula girl survived, though, which was the important thing. I started the project before I thought to document it with photos, so here's a quick recap: That problematic oak plywood that gave me so much trouble on the porthole? The scrap was perfectly-suited for this project. I cut two squares of 9" and 8", then sanded, stained and glued them together. I used my router to cut out a cavity to hold a music box, then drilled a hole through for the winding key (after carefully measuring everything). I returned to Ebay to get a Reuge music box movement. I looked in vain for one that played "Joe's Lullaby" and briefly flirted with the idea of using a digital audio recorder to capture that song and play it back, but that would've added several layers of complication to an already challenging project. In the end, I settled for a music box movement that played "Lovely Hula Hands," which I thought an apropos substitute. Then I cut, stained and glued on molding trim to finish out the base before adding plastic furniture footers for the lamp base to stand upon.

Rather than attempt to cannibalize an existing lamp, I picked up a lamp kit from Lowes that included a long, threaded central rod I cut to the length I needed. This past year, I'd been harvesting and scorching quite a bit of bamboo. One piece in particular stood out--it had a series of bulbous nodes packed closely together so that it resembled a sword grip or somesuch. In fact, my son used it as a ninja sword on more than one occasion. The piece of bamboo was too narrow to effectively use in the tiki bar, but it was the perfect size for the lamp. I cut it to length, knocked out the interior nodes then threaded the rod up through it. After that, I bolted it to the base and attached the socket. All pretty straightforward.

Next, I placed the hula girl on the base and traced along her base. Then I routered out a depression for her to sit in for increased stability. Note: Somewhere along the line I coated everything with a good application of polyurethane, but I forget exactly where. Feel free to insert that step wherever you think most likely.

The bamboo and statue wanted to overlap and occupy the same space, which wasn't acceptable. Rather than notch the statue, as I've seen others do, I opted to shave out an appropriate crescent from the bamboo using my band saw. Worked out pretty well.

The next step was a bit nervous-making. To solidly, securely attach the statue to the base, I decided to use epoxy. Once epoxy sets, it's set. It won't let go. There's a window of opportunity to get everything matched up correctly, but if you're not settled by about 6 minutes in, you're out of luck and going to have to start over, which is a pain, because there's all that hardened, resinous epoxy to clean away. I'm happy to report that things went well. The epoxy stayed where it was supposed to and didn't get all over everything or go awry. The statue was firmly anchored and not going anywhere.

Next, the lamp shade. This was, beyond a doubt, the biggest pain-in-the-ass of the whole affair. One person online reportedly tracked down the original artist who designed the lamp, and got a copy of the lampshade artwork directly from them. But when people started asking if he could share the art, said poster abruptly went silent. An online posted by the handle of Jintosh cobbled together a pretty good reproduction of the shade by using screen captures from the film and faking the rest. Unfortunately (I use that word a lot) the most common custom lampshade printing source--Zazzle--only had shades of a significantly different aspect ratio than that of the shade from the film. To make it fit, the users online simply adjusted the dimensions of Jintosh's artwork, which resulted in horizontally squashed, vertically elongated images. I have OCD that manifests in different ways, and that distorted aspect pushed all the wrong buttons for me. What I ended up doing was taking Jintosh's original, uncompressed image and slicing it apart in Photoshop, so that I could recomposite the three scenes more closely together. The distinctive ocean waves simply would not line up when I did this, so ended up replacing it with actual ocean. Ditto the sailboat and storm cloud. I rebuilt the moon and clouds and dramatically enhanced the torchlight procession up the side of the Big Wu volcano. The beach scene was the most challenging, carving out plants and sand and sunset for space without it appearing chopped up and reassembled in a haphazard manner. In the end, I think I managed a convincing job, although anyone comparing it to the original artwork might be shocked at how many liberties I took.

When the shade arrived, my heart sank. The print job was gorgeous, but the shade itself was of the uno fitting type, which is a ring that sets around a socket designed for such. Every lamp I've ever had--and the lamp kit I built my lamp out of--was of the harp-and-spider type, where the lamp shade is threaded onto the top of the harp and held in place by a filial. I'd even tracked down a decorative pineapple filial like the lamp in the movie. Needless to say, the Zazzle site did not indicate anywhere that this particular lamp shade was of the uno type, and they were very slow in responding to my emails and pretty defensive at that. To make matters worse, it appears that at one time brass uno-to-harp adapter rings were common, but haven't been produced for a long time and now are either completely unavailable or outrageously expensive. In the end, I cobbled together a makeshift adapter using a steel reducing washer as a base and a PVC pipe reducing bushing (or something similar--I didn't pay close attention when I bought it) that I ran through the bandsaw to shave it down to the proper depth. Sandwiched between the washer and bushing on top of the harp, the uno fitting stays pretty much in place. It's perfect, but I was running out of time and couldn't be picky.

To finish out the lamp shade, I used the rubbery glue "Goo" to attach a length of manila rope along the top of the lamp shade, holding it in place with plastic clamps until it dried. This was a pain, because the rope kept wanting to coil and smeared the glue around before I got everything secured. Once that dried, I repeated the process with a piece of raffia table skirting I'd cut to size. And yes, the raffia behaved just as badly as the manila rope. But I finished it in time for Christmas, which was no small feat.

The Wife, I'm happy to report, seemed suitably surprised. "No way," she said upon opening the package. "These don't exist!" At first she thought I had ordered one from someone who custom made them to order. When she found out that I'd built it myself in the garage over the previous month, she said, "But weren't you afraid of me walking in on you?" To which I answered, "You did! Over and over again. It wasn't easy to disguise what I was working on. Plus, you weren't really paying attention."

So, while this lamp is definitely tiki-esque, it's pretty doubtful that it will ever spend much time in my tiki bar.

Now Playing: Pink Floyd Ummagumma

Chicken Ranch Central

Chicken Ranch Central

Friday, December 22, 2017

Friday Night Videos

It's December 22, so that means it must be time for the Kinks' "Father Christmas," one of the greatest, most subversive, Christmas songs ever. Enjoy!

Chicken Ranch Central

Chicken Ranch Central

Friday, December 15, 2017

Friday Night Videos

I've long been vaguely aware of Charlie Byrd, but to be honest, he's an artist I've never paid much attention to. I just never came across his work, really. A month or so back, though, there was an estate sale near me and although they didn't have much of interest, there were quite a few old vinyl LPs dirt cheap. I picked up a few, one of which was Charlie Byrd's Bossa Nova Pelos Passaros, which I didn't get around to listening to until last night. Holy moly, but this is a mighty fine example of instrumental guitar bossa nova. I feel cooler just listening to it. "Meditacao (Meditation)" was a big hit for him back in 1962, and it holds up impressively today. Check out his finger work in the video!

Chicken Ranch Central

Chicken Ranch Central

Friday, December 08, 2017

The Great Blizzard of '17

Growing up in central-ish Texas, a White Christmas was never in the cards for me. A white anything was never in the cards. Television and movies insisted on lying to me, and I thought our snow-free holidays merely an troubling aberration we suffered through whilst the rest of the world had snowball fights. Every year, I asked for a sled. Santa, wisely, did not deliver on that request.

Don't think Texas is all desert and heat, thought. I'm fond of saying I tolerate August here so that I may wear shorts in January (true) it does get cold here. It freezes here, although cold spells lasting more than a week are uncommon. We get ice storms. We get frost. We get sleet. But snow? Not so much. Growing up in tiny Columbus, the only real snowfall I ever experienced came around 1973, with a big front that blew in and chilled things for the better part of a week. We got around 6" on the ground, and neighbors and friends came from all around to sled down a big hill at our house in cardboard boxes. There were snowmen, snowball fights and grainy Super 8 film footage to document the occasion. I've never experienced anything like that since. Sure, around 1976 there was a modest snowfall--maybe 1"--but not enough to make more than a tiny snowman. In 1987 during the day at high school we had a wave of sleet followed by about an hour of modest snow flurries, enough for accumulations to build up on the cars in the parking lot, prompting a snowball fight during lunch. In 1995, there was a serious ice storm in Temple, but no snow. In 2003 there was a super-cold ice storm that shut I-35 down, but no snow. The next year (of the year after) a front skipped over us and dropped a lot of snow on the coast, so the next day we took the kids to Cuero to visit my grandmother and play in the pockets of snow that survived in the shadows of buildings.

Last night, defying predictions, we experienced an honest-to-goodness snowfall. The Wife and girls had gone to Wassailfest in New Braunfels. I stayed home trying to cover my banana plants to protect them from the rapidly falling temperatures. During all this, big, puffy white flakes began falling. I called Bug out. He went nuts with excitement. To make a long story short, the snow came down so fast and so thick that it stuck. It couldn't melt fast enough. Bug made a snowman so large that he needed help lifting the pieces atop one another. Then he made a snow cat so the snowman could have a pet. He did a pretty good job, considering he started with zero experience. Not too many snowmen I've ever seen use chunks of palm tree bark for buttons and sections of bamboo for arms and nose. He challenged me to a snowball fight, then decided snowball fights weren't his thing when he learned how fast his dad could make and throw snowballs.

This morning, reality had retaken control. The roads and driveways and sidewalks and other impervious surfaces had all melted clear. The snow on the ground and in the trees had compacted and turned icy. It still looked impressive, for the most part, but wasn't much fun anymore. Still, there's something about snow on palm trees that just demands to be photographed.

Upon arriving at work this morning, I saw that the Texas State students had just as much fun on campus as we'd had at home. Snowmen--or at least their remains--abounded, as did evidence of snowball fights. And I encountered my first-ever snow angel in the wild. All in all, it was a fun 24 hours.

And despite two C9 light strands shorting out on me, I did manage to get all the banana plants wrapped and protected. So that's a win as well.

Now Playing: Antônio Carlos Jobim Wave

Chicken Ranch Central

Chicken Ranch Central

Tuesday, November 21, 2017

Tiki build-along, pt. 14

Remember how yesterday's Tiki build-along installment was really short? Well, hold onto your mai tais, folks, because what follows is huge. Enormous. Long, even. With lots of photos.

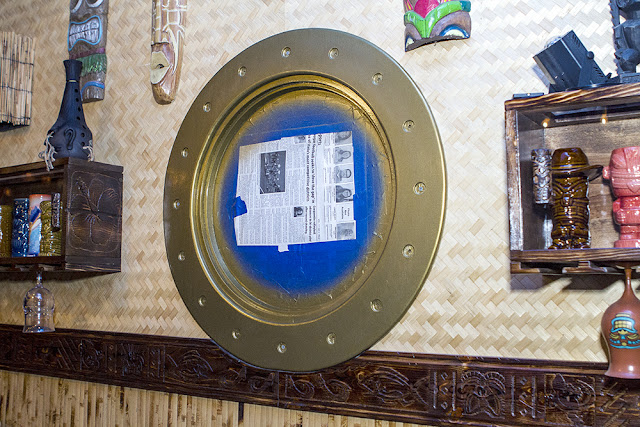

Those playing along at home may recall certain references I've made to the bathroom porthole window on the patio. I started tearing it apart here and you can catch glimpses of it in situ here and in other posts if you're of a mind to look. When we first moved in, we thought it was kind of cool. But as I started tikifying the patio, that window grew dramatically less cool. The frame was made of four semi-circular pieces of wood that didn't join up very well. Worse, the wood and metal window edging had been coated with some kind of tough, textured paint/resin thing that hadn't aged well and accumulated dust. It had to go.

Here's the thing: A round window like that needs to enjoy a ship's porthole aesthetic. It just does, especially for a tiki bar, which naturally encompasses a certain nautical aesthetic. The problem, though, is that actual brass ships' portholes cost hundreds, if not thousands, of dollars. And this window is large--31" across, which is enormous for an actual porthole. So even if I could find one that would fit, 1) it'd be way too expensive for my budget, and 2) way too heavy for the wall. Crap. After spending the summer avoiding the issue, I finally broke down and admitted I'd have to try and fake one. I resisted this for a long time, because the last thing I wanted was something that looked like a slab of plywood painted gold. Let me introduce you to what would become my personal hell for the next few months:

Certain of you think I know what I'm doing when it comes to woodworking. Hopefully, this will dissuade you from that notion forevermore. In my misguided way of thinking, I spent real money and bought the nicest 4'x4' sheet of oak plywood I could find. My thinking here is that oak, being hardwood, would be the best material for my shaping and sanding and tweaking into a fake brass porthole. Wrong. Apart from some kind of crappy sub-flooing plywood or particle board, oak was probably the worst choice I could've made. In addition to it being more expensive, oak is primarily valued for its dramatic, pronounced wood grain. Keep this in mind, it comes into play in a little bit.

I needed the plywood to be cut into a circle. How to do that? I knew better than to try and freehand it with a jig saw, but routers have an attachment that allows circular cuts. Those attachments are too small for my needs, but I figured I could rig something up. First, I marked the center of the 31" circle I needed on the plywood, then screwed an anchor screw right in the center.

The plywood was 3/4" thick, so I chose a narrow router bit and set it for a depth of about half the plywood's thickness. That way I'd make two passes and not stress the trim router's motor as much as I would by making one single, deep cut.

See? About halfway through the thickness of the board. All I can say is that it made sense at the time.

This is my super-high-tech circle-cutting jig: The short circle-cutting jig the router came with, and a length of garden wire. I'm using the trim router rather than my big Skil router because the big one, although probably better for this job, had no way to attach the jig to it.

And, here I go! There are three photos here of my routing out a circular cut because The Wife was kind enough to photograph me on this fool's errand. Her photos are always much nicer than mine, so I didn't want them to go to waste.

Here is the first cut. I then made a second pass to complete the cut.

Here is the second, inner cut. I managed this by the technical process of tying the wire shorter.

Look, folks! A wooden donut!

Alas, here's the first place the oak burned me. Being a hard wood, the router bit snagged and jumped repeatedly during my cuts. This resulted in gouges and ugly scratches and miscuts along the length of the circle. Remember how I wanted to make this look indistinguishable from an actual brass porthole? Crap like this doesn't help.

If there's one thing I've gotten good at, it's improvising solutions to cover up my screw-ups. In this case, repair involved copious amounts of wood putty. In this case, the repair worked out well--the putty sanded down very smooth once dried. Had I been smart (ha ha) I'd have glopped putty over the entirety of exposed wood surface. I'm not smart, and I didn't.

Now that I had the big wooden donut roughed out, I could start work on the center trim pieces. Drafting complaining children to help me, I held the 1"x6" center trim pieces of ponderosa pine in place and traced the intersection of the donut over them. Now I knew where to make the cuts so the trim would meet properly. Surprisingly, this part was relatively painless.

Cut marked on both trim pieces to accommodate big wooden donut.

Cut made!

Now, ever porthole needs rivets to complete the aesthetic, right? I marked the center of the donut at the four cardinal points, then four more at the halfway point between each. After some consideration, The Wife and I agreed that eight rivets did not sufficiently sell the illusion of portholyness, so I double the number to 16. Yikes!

I used a straightforward 1" drill bit to make the cuts.

The process was easy, but time-consuming. I had to get the hold deep enough for the wooden mushroom buttons I was using for rivets, but not so deep so as to cut all the way through.

I knew I'd screw this up, but somehow I didn't. You can also see the buttons below, after several coats of sanding sealer and several coats of metallic brass paint.

Way back at our old house I recalled using sanding sealer to get a nice, smooth polish on my bookshelves, so I chose to use sanding sealer on this oak to get a nice, smooth polish. Apply, let dry, sand lightly and repeat. Repeat about a hundred times over the ensuing month in a futile attempt to get a smooth, featureless surface that could pass for metal. This was the definition of tedium. Whilst that was going on, I also busied myself with the center trim pieces. I printed out and cut templates from cardstock so that it'd be durable enough to use multiple times. I traced these stencil patterns over the wood to guide me in my carving.

Unlike the base trim, which consisted of a repeating triangle pattern, I had this notion that since the center pieces were more visible, they needed a wider variety of designs. So I made way too many different patterns and used them all.

I wanted to add occasional tiki faces as well, but they were too complex to make an actual stencil template. So instead I sketched them out on a square of paper, then copied them freehand onto the wood. This might be a good place to mention that I can tend toward the obsessive at times. The Wife enjoys reminding me of this at every opportunity.

The tiki faces were too detailed to use the trim router on, so I spent a considerable amount of time carving them out with the Dremel. The Dremel got lots of use. It's slow going, but can't be beat for detail work. Unfortunately, I had lots of detail work. My ambitions outstrip common sense more often than not.

Once I finished carving everything out, I hit the boards with an angle grinder to add nicks and gouges to simulate the wear and tear of age, then pulled out the butane torch and scorched 'em all. Here's the result.

After that, I applied the wire brush to scrub off the carbonized wood (soot, if you will). Curiously enough, when I'm scrubbing, it smells of burnt marshmallows. I assume it's the wood sugars carmelizing under the heat. It's not unpleasant, but certainly weird.

At this point, after several weeks of work, I judged it was time to paint the big wooden donut. I judged wrong. A can of metallic brass spray paint only succeeded in showing me that oak grain is very, very durable stuff. It looked exactly like a cheap piece of plywood painted brass in a misguided attempt to make it look like a ship's porthole. Even without the prominent grain, it still looked very plywood-ish. The Wife suggested beveling the edges of the big wood donut. I thought "What the hell?" It certainly couldn't hurt.

So I beveled the crap out of that big wooden donut. Fortunately, I already had the router bits I needed, so no additional expense was incurred.

I also took my power sander and sanded down the paint and sanding sealer and wood grain. I sanded and sanded and sanded some more. When the power sander started doing more harm than good, I hand sanded that sucker. Was I overdoing it? Maybe, but I didn't have many options left. Instead of the sanding sealer, this time I applied coats of water-based spar urethane. It wasn't as thick as oil-based spar urethane and so didn't build up as quickly, but it was thicker than the sanding sealer and dried fast allowing me to apply several coats in one evening.

Which brings us back to the metal window frame. The one with that resinous/texture/paint stuff on it. The stuff that didn't want to come off. I used sandpaper, utility knives, paint scrapers, razor blades and a host of other items to remove that crap from the metal. Even moreso than woodgrain, crappy paint texture painted brass would spoil the illusion I was trying to create. I worked on this for weeks. It was awkward to reach. The various curved angles presented a unique challenge. It wasn't until I started using a wet sanding sponge that I started making real progress.

This same sanding sponge, when dry, was fairly ineffective. But once I got it wet, it started stripping that crap away. Thank goodness.

Somewhere along the line, I scraped all the white spray paint from the window. It was an ugly, half-assed privacy screen. Scrape, scrape, scrape. All gone. I wish everything else had been so easy. I used old newspaper and painter's tape to mask off the window glass in preparation for painting. I used a razor to trim the tape to form.

I ended up using more tape than I'd intended.

But what about overspray? Well, that called for more tape and lots of plastic sheeting. About this time a cold front blew through. The temperature didn't change much, but the damn wind whipped all that plastic around and pulled things apart repeatedly before I manage to get it all secured.

I kept an eye on the palm trees surrounding the pool. When they settled down, I got in a few seconds of spraying before the wind whipped them up again. Using this guerrilla approach, it only took me about three hours to apply a couple of coats to the metal window frame. The next day I added a coat of gloss enamel.

I used two cans of metallic brass spray paint to the big wooden donut. The good news: I succeeded in eradicating all traces of wood grain. The bad news: The spar urethane was showing brush strokes. ARGH! Well, too late now. The brush strokes were visible up close, but not from a distance. It would have to do. And here's a little bit of cleverness--those circular holes for the rivets/buttons? The pilot point of the bit made for a perfect fit for screws. I held the big wooden donut in position, drilled a pilot hole into the fiber cement siding behind it, then secured it with long, outdoor screws.

I secured the big wooden donut to the wall with screws at the cardinal points. Suddenly, it's not looking quite so much like a big wooden donut anymore.

Remove the tape and newspaper, and add the mushroom buttons, if you squint just right, it kinda sorta looks a little like a brass porthole. I must confess this final step was not so easy. Turns out the paint and spar urethane added just enough thickness to the edges of the holes that the mushroom buttons would not fit. At all. So I had to break out the 1" drill bit once more and clean them out, once by one. Shavings of paint and urethane rained down like snow. Which was a mess to clean up. To get the mushroom buttons in place, I set them in their respective holes, placed a sheet of wax paper over each, placed a leather belt over that, then gave it a couple solid whacks with a wooden carving mallet. This elaborate dance was designed to avoid marring the paint on the buttons. Believe it or not, those were the only things that seem to have turned out flawlessly.

And here is a shot of the finished product for comparison with the initial image in this post above. It doesn't look bad from this angle, but then again, I know all the flaws and I'm certain they will trouble me the rest of my life. Still, I guess compared to dropping a couple of thousand on a for-real brass porthole, it's a bargain at twice the price.

Now Playing: Carlos Lyra Bossa Nova

Chicken Ranch Central

Chicken Ranch Central

Subscribe to:

Posts (Atom)